I would like to dedicate my I search project to Pam, for helping me finalize all of my writing work. My mom for helping me with ideas and correcting my work. And my dad for also helping me with finalizing my magazine.

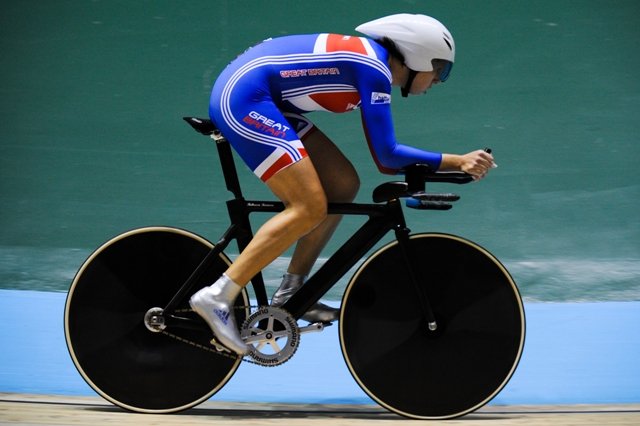

The LZR suit by Speedo is the fastest swimsuit ever built. The suit was banned after the 2008 summer Olympics because it held in air between the suit and the body.

These shoes are 3d printed, they have not yet been in the Olympics. Forsan, the designer of the shoe is confidant that the runner who is wearing his shoes will win gold.

Wind tunnels also help engineers by correcting the computers mistakes and to test wind flows that computers can’t show.

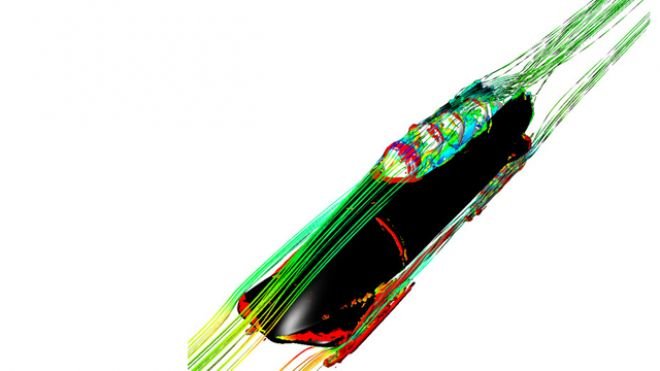

Luge is a sport that goes ovre 90 miles per hour. The luge turns when pressure is placed by the legs on the runners. The sport is timed at thousands of a second so ever change on the sled makes a difference.

Wheel chair racing needs a lot of technology, the frame and wheel are mostly made out of carbon fiber. The races are short for these speed machines so the design is as important as the athlete.

Skeleton is a sport like luge but not as fast and head first. Many do not know that it is only a tiny bit more dangerous that luge.

1533 Madrono Ave

Palo Alto, CA 94306

Dear Reader:

I am a mechanical engineering professor at Stanford University. I have been teaching engineering for 11 years. I have given many opportunities to work on major projects. Most people don't know that engineering is in everyday use. That is why am constructing magazines with the help of my intelligent students. Over the last four years, I have gotten all of my students to put together magazines.

In this month’s magazine we have three special articles and lists. The first one is an article about the luge sled and how it was recreated from scratch at Clarkson University. It explains the steps engineers took to the luge sled faster. The second article is about the BMW bobsled. The BMW bobsled article explains how the US bobsled team won medals for the first time in 62 years. Finally, the third article contains our ‘top three’ lists for sport technology

Don’t forget to visit our design studio to see a great display. It is a model of an wind tunnel. It is made out of legos and replicates the real tunnels, but on a very very small scale. Also, take time to look over our photo book with explanations. Some of the photos refer to the articles, and some are photos which go into more depth about sport technology topics.

I have learned a lot from this research, with the help of my students. We have learned that sports engineering makes people want to learn more about the process of improving sports performance. When sponsoring companies like BMW advertise their involvement, people are more likely to watch the Olympics so that they can see the results of the engineering. Because NBC hosts the Olympics, they make more money when more viewers watch. Also, engineering will change the future of sports, raising them to the next level. These articles show that we learned new ways of engineering to improve speed and durability.

I love this kind of work because I can teach it to my next class. It also helps me understand the expansion of engineering. I love my work because I get to change kid’s lives; the the jobs they get and helping them in life. Like all inventing processes, there are many false starts, ideas that don’t work and dead ends, but when the work is done, it is worth the trouble.

Of all the magazines we have published, this issue surprises the most. I think that the next issue will be engineering sport cars. It will give readers an idea about how these cars can reach high speeds and still be safe at the same time.

Sincerely,

Professor Davis

One of my favorite professors,

is Dr. Helenbrook. He is one of the head designers for the USA luge project. When he invited me to accompany him to Lake Placid, to watch one of the sled models race, I agreed immediately.

Lake Placid sliding center.

Mark Grimmette had won two Olympic medals in luge, and Kennedy is th first American to win a luge world cup. Grimmette and

Kennedy were grateful to have someone to help with the sleds, so they agreed. Helenbrook is a family friend of the Bohls, so he went to also work with on the project.

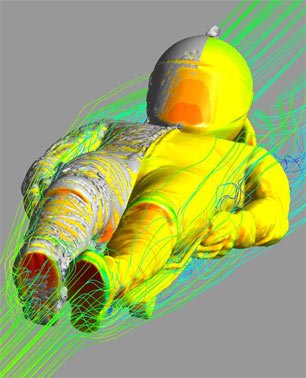

Bohl and Helenbrook are also working with Dow Chemical on the project, which aims to reduce drag and improve aerodynamics.

Another important factor is to increase the comfort of the sled.

“If the athlete fits well and

can be

comfortable in the sled, the overall performance will improve too,” Bohl said. They are using computer programs to simulate models and ideas of the frame. Once they find a computer design that works, they build the sled out of carbon fiber, using computer controlled machines. The computer programs save a lot of money. Instead of making many sleds, the designers can choose the best computer models, so they only make a few. "We're getting to the piont where we can work with technology to improve the sleds," Bohl said. This sled will eventually be one of the firstluge sled designed by a computer. In the past, all luge sleds were handcrafted.

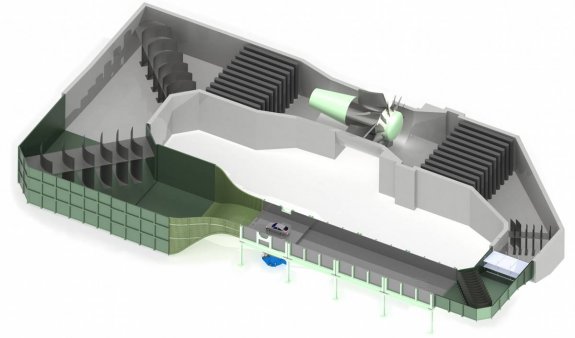

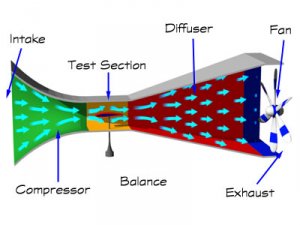

Wind tunnels matter just as much as computer programs. Wind tunnel tests test the aerodynamics of the sled and the person on it. These tests can point out mistakes by the computer, and see what needs to be changed. A wind tunnel is a big tube with a turbine on one side, which sucks in air and pushes it into the test area. The test area is where the projects are placed, in this case the athlete and the sled are placed in the project area. In the test area, smoke comes out of a nozzel that's on a wand that a person can control. The

smoke then travels with the air around the object placed on the ground. Then viewers can clearly see which parts need improvement. After the air passes the test area, it travels

back into the turbine.

The US two man bobsled racers have won bronze in Sochi, Russia. This is the first Olympic medal for US men’s two man bobsled in sixty two years. The medal was made possible thanks to improved technology. BMW helped the US team out by redesigning the bobsled.

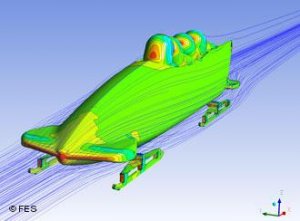

Michael Scully, the head designer at BMW Dreamworks in California, was the leader of the project. Scully and his crew created computer models using a simulator, and the fastest were chosen to be made into prototypes. The prototypes were then tested in wind tunnels to see if any more improvements could be made.

One of the biggest issues faced by the team was weight. Minimum weight for the sled (excluding crew) is 170kg. Maximum weight (including crew and equipment) is 390kg (Women’s sled: 340 kg.). Most of their early prototypes were less than the minimum weight. Scully had to move the weight around in strategic places so as not to slow down the bobsled. Also, the track in Sochi had up hills. Uphills are a challenge for bobsled builders. The uphills add another obstacle. During an uphill, the sled has to maintain speed or the race could be lost. The bobsled needs to be fast on downhills while maintaining speed on the up hills. Scully has to find a design that would do that.

After the final prototype was finished, it was tested on the Lake Placid Sliding Center. The team tested many versions of the sled to find out the fastest of the fastest. The new design was made into six sled, three for the women’s competition and three for men’s competition.

The four man bobsled is most likely to be redesigned next. The four man bobsled won gold in Vancouver 2010 winter Olympics. However, this year they won bronze. If they had improved sleds, they could have gotten second or possibly first. Russia got first in the two man and the four man bobsled races in Sochi. Russia got first in both events, this was partly because they could train on the track before anyone else could. They got the most practice out of all the competitors. Many wins the the Winter Olympics and Summer Olympics are made possible by technology. Also, in the paralympics.

Top 3 Rules For Constructing a New Model

1. Use a wind tunnel. Wind tunnels are used for improving aerodynamics of an object. Wind tunnel tests allow designer to see the parts of a design that slow it down.

2. Use computer apps. Computer apps can simulate aerodynamics and drag. This can save thousands of dollars by eliminating many mistakes before a model is made. Instead designers can just move or change a part of the design with the click of a button.

3. Take comfort into account. Comfort can change the performance of an athlete. If the suit or structure is uncomfortable the athlete can be distracted. The athlete may have to change their form to accommodate the discomfort, which will slow them down.

Top 3 New Innovations Used In The Olympics (From 2000)

1. Speedo LZR swimsuit. The suit is built for speed. It has shark skin design which improves speed. The LZR suit also is ultrasonically stitched together to reduce drag.

3. New sprinting shoe. The new shoe is shoe that weighs just 96 grams (3.4 oz). According to Fusaro, his technology allows making shoes that could improve an athlete's performance by up to 3.5%.

BMW bobsled. The US men's two man bobsled had not won a medal in over 60 years. This newly designed bobsled won bronze of the team.

Mock 39 Under Armour speed skating suit. The suit gave no medals to the US team. It claimed it was the fastest suit in the world but actually slowed down the athletes.

Speedo LZR swimsuit. Although it is the fastest swimsuit ever created, it was banned from swimming. The suit trapped air inside which gave an unfair advantage to athletes using it.

Death of luger. The death of Georgian Luger in 2010 at the Vancouver Olympics. He crashed into a metal pole on the outside of the track. Many people said it was the driver’s fault but an FIL official admitted to that the accident was, “Their mistake, the track was not built correctly.”

Carbon fiber. Carbon fiber is a lightweight material and also strong and flexible. It is usually used in racing sports for speed.

Back Next

Magazine Posts

Magazine Posts Table of Contents

Table of Contents